Metal Fabrication Gastonia NC | Laser Cutting, Forming, Welding | Farris Group

Gastonia companies in utilities, logistics, building products, and equipment manufacturing rely on metal parts that fit correctly and withstand daily use. Farris Group delivers metal fabrication services in Gastonia, NC, producing brackets, enclosures, skids, platforms, guards, machine frames, and light structural weldments in carbon steel, stainless steel, and aluminum.

Work follows an ISO 9001:2015 certified system covering programming, cutting, forming, welding, inspection, and shipping. Drawings are reviewed for material grade, thickness, bend radii, hole locations, GD&T, and weld symbols. Revision control and routed travelers ensure builds match the latest print.

Cut. Form. Join.

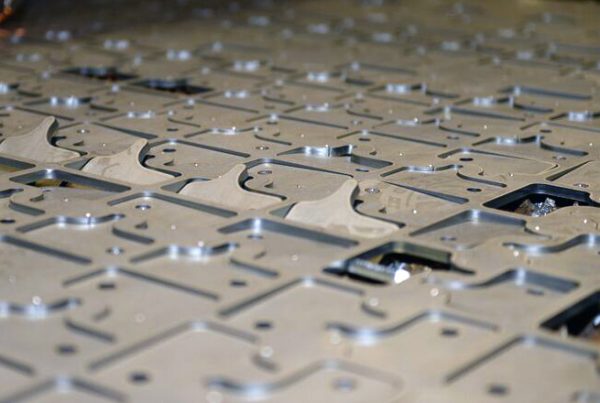

Flat patterns are created on CNC fiber lasers that balance speed and edge quality while protecting small features and hole position. Programs are nested to optimize sheet yield and maintain thermal stability. Parts move to CNC press brakes, where programmed setups, staged tooling, and calibrated gauges hold bend angle and flange length. Multi-bend parts receive sequenced operations and fixtures to control springback and preserve geometry.

Assemblies are completed with MIG and TIG welding, performed by certified personnel. Robotic welding cells support repeat work that benefits from uniform seams and high throughput. Fixtures manage alignment and minimize distortion on long members and box frames. Welds are inspected for penetration, appearance, and location. Dimensional checks confirm datum-to-hole relationships, hinge points, latch landings, and interface heights. For builds that specify additional verification, penetrant testing or coordinate measurements are coordinated and recorded.

Material selection is tuned to the application. Stainless grades support washdown, outdoor, and corrosive environments. Coated carbon steel provides rigidity and cost efficiency with appropriate protection. Aluminum alloys hit weight targets and reduce handling strain. Farris Group integrates hardware installation for PEM inserts, hinges, latches, and seals, and coordinates finishing such as powder coating, priming, or galvanizing. Kitting and labeling are offered by subsystem or installation phase to reduce receiving time and staging effort.

Proven Compliance and Reach

Gastonia contractors that touch public infrastructure value complete, traceable paperwork. Farris Group is a FedLinks Verified Federal Vendor, and supplies material certifications, welder qualifications, weld procedures, dimensional reports, and inspection logs according to procurement requirements. Documentation ships digitally and with the order, which simplifies submittals and audit readiness.

Logistics are planned around customer calendars. Shipments can arrive as bulk pallets, serialized kits, or grouped subsystems. Labels map to line numbers, station cells, or job phases so teams can stage parts immediately. Communication during production keeps schedules visible and reduces risk.

Ready to get started? Speak with a fabrication expert now at 704-629-4879 or visit our website at Farrisgrp.com to request an expert consultation.

We deliver across the United States, Canada, Mexico, Germany, Western and Central Europe, and Turkey.

Frequently Asked Questions about Fabrication Services in Gastonia, NC

Can you provide First Article Inspection?

Yes. FAIR is available for new part numbers.

Do you coordinate galvanizing for outdoor service?

Yes. Galvanizing and powder systems are scheduled per specification.

Is serial labeling available for maintenance tracking?

Yes. Parts can be serialized and logged by lot.