CNC Machining Troutman NC | Milling, Turning, CMM

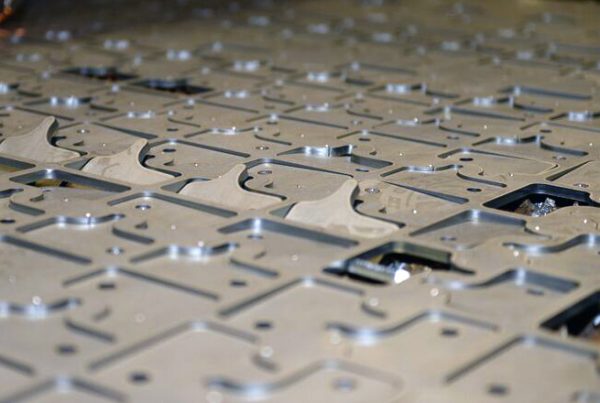

Farris Group provides CNC machining services in Troutman, NC for carbon steel, stainless, and aluminum. Typical outputs include housings, precision plates, spacer stacks, shafts, and bracketry.

Operations run under ISO 9001:2015 certification with travelers, tool-life tracking, and calibrated gauges. Drawings and models are reviewed for GD&T, datum hierarchy, and thread standards before release.

Milling, Turning, and Metrology

3- and 4-axis milling handles prismatic features using high-efficiency roughing and measured finishing paths to protect flatness and surface quality. CNC turning controls concentricity and runout for shafts and bushings; live-tool features are completed in one setup when geometry allows. Hole-making cycles control drilling, tapping, and reaming, while precision bores are finished with boring heads to achieve true position.

Verification blends in-process gauging with final checks on a CMM or height-stand routines for critical features. Standard production targets ±0.001 in capability on common geometries, with tighter windows quoted when supported by process capability. Stainless details can be passivated on request; aluminum parts can be routed to anodize or coating. Parts ship tray-packed or kitted by subsystem with labels that mirror work orders.

Docs, Logistics, Reach

Farris Group is a FedLinks Verified Federal Vendor, and supplies material certificates, dimensional summaries, and thread-gauge results as requested. Freight is scheduled to receiving windows, and labels map to cell locations or zones to speed staging.

Request a machining schedule for Troutman at 704-629-4879 or submit RFQs at Farrisgrp.com.

Service includes the United States; Germany; Western Europe.

Frequently Asked Questions about Machining Services in Troutman, NC

Can you mark parts with QR codes for traceability?

Yes. We can engrave part IDs or scannable codes tied to reports.

Do you provide fixture development for complex parts?

Yes. Workholding is designed to stabilize features and reduce stack-up.

Are mixed metal runs possible in the same order?

Yes. We route by cell and protect tooling and finishes accordingly.