CNC Machining Boiling Springs NC | Precision Milling and Turning | Farris Group

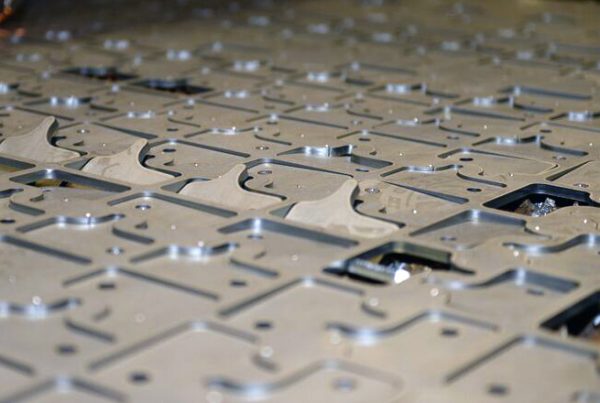

Boiling Springs manufacturers work with equipment that depends on accurate machined parts. Farris Group supports these needs with CNC machining services in Boiling Springs, NC for carbon steel, stainless steel, and aluminum. Typical components include mounting plates, bearing blocks, turned shafts, spacers, brackets, and small manifolds used in mechanical and fluid systems.

The machining operation runs inside an ISO 9001:2015 certified framework. Every job has a defined sequence, calibrated tools, documented inspection points, and a record of the revision that was produced. This gives production and quality teams confidence that parts stay aligned with the print over repeated orders

How the Machining Process Is Structured

Before a program is released, engineering reviews the drawing and any supplied model. Datum structure, GD&T requirements, tolerances, and thread specifications are confirmed.

On the shop floor, 3 and 4 axis milling handles prismatic parts. Tool paths are selected to control cutting forces and protect surfaces. Fixtures and vises are chosen to maintain flatness and perpendicularity. CNC turning is used for shafts, bushings, and other round parts that require concentricity and controlled runout. When the geometry allows it, live tooling is used to mill flats, drill cross holes, or add key features in the same setup.

Holes are drilled, tapped, and reamed by controlled cycles. Bores that affect alignment or sealing can be finished with boring heads that are set and verified to size.

In-process checks use hand gauges, micrometers, and probes on the machine. Final checks on critical dimensions can be performed on a coordinate measuring machine or a height stand and surface plate. Many production programs target around ±0.001 inch on important features, with tighter tolerances available when the design and process support them.

Stainless parts can be passivated if requested, and aluminum parts can be routed to anodizing or coating. Parts are deburred to the specified edge break and marked when traceability is requested. Packing uses tray systems, sleeves, and kitted cartons built around the customer’s assembly plan.

Quality Records, Shipping, and Service Regions

Farris Group is a FedLinks Verified Federal Vendor. For programs that require it, they provide material certifications, dimensional reports, and thread gauge summaries. Records can be shared in digital form and travel with the shipment.

Shipments are scheduled with the buyer’s dock and production requirements in mind. Part labels can follow the customer’s internal part numbers or project codes.

For CNC machining in Boiling Springs, NC, contact Farris Group at 704-629-4879 or visit Farrisgrp.com to request a machining quote and review lead times.

Delivery & Service Areas: United States; Canada; Western Europe.

Frequently Asked Questions about Machining Services in Boiling Springs, NC

Can you supply sample parts before full production?

Yes. First article parts can be produced and documented before the main production run.

Do you accept both 2D drawings and 3D models?

Yes. We can work from traditional prints, models, or both, as long as the revision status is clear.

Can you manage machining, coating, and final kitting under one purchase order?

Yes. We can route parts through multiple internal steps and provide a single completed kit.