Powder Coating and Painting Mooresville NC | Industrial Metal Finishing | Farris Group

We work with Mooresville manufacturers who need metal parts finished on time and to specification. Our industrial painting and powder coating in Mooresville, NC cover carbon steel, stainless steel, and aluminum. Typical parts include brackets, control panels, frames, machine guards, and weldments that move straight from our racks to your assembly lines.

Our finishing operation follows a documented ISO 9001:2015 certification quality management system. Every order is tied to a routed traveler that tracks pretreatment checks, gun settings, cure records, inspection results, and packing instructions. This gives your quality team clear visibility from raw metal to finished component.

Our Coating Workflow from Pretreat to Inspection

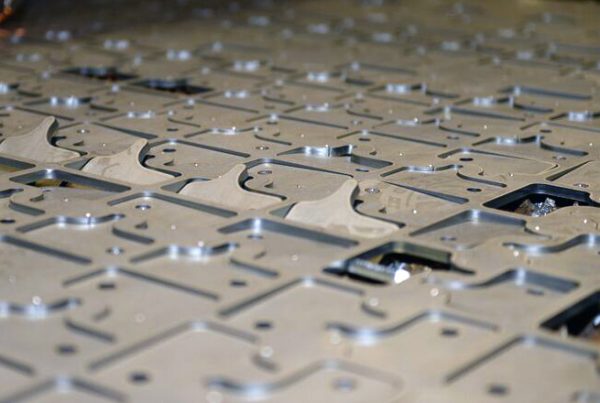

We begin with cleaning. Parts go through alkaline wash and rinse stages to remove shop soils, oils, and light oxidation. Based on material and service conditions, we apply iron phosphate for steel or a zirconium conversion coating where a higher level of corrosion resistance is desired. For heavy weld scale or rough surfaces, we add media blasting to create an anchor profile that supports long term adhesion.

Our masking plans protect threads, sealing faces, and ground points. We use silicone caps, high temperature tapes, and custom plugs to keep these areas clean while still allowing for reliable grounding during electrostatic application.

Powder coating is applied in enclosed spray booths using electrostatic guns. Our team monitors gun distance, angle, and flow to maintain uniform coverage and avoid thin spots in corners or recesses. Most exterior systems target a 2.0 to 4.0 mil dry film thickness range. Where the specification calls for liquid coatings, we apply epoxy primers and urethane topcoats designed for chemical and UV durability.

Cure is verified with metal temperature probes and logged time at temperature. After the parts leave the oven and cool, we perform film thickness checks, visual inspection, and adhesion checks where required. Orders that need formal documentation can receive recorded DFT logs and test results.

Packaging is planned for real world handling. Parts can ship bulk on protected pallets or in kits assembled by subsystem or area. We use foam, edge guards, and interleaving to protect the finished surfaces.

Documentation, Logistics, and Where We Ship

We are a FedLinks Verified Federal Vendor, so we can support Mooresville projects that require traceable prep logs, film thickness summaries, cure records, and certificates of compliance. Our documentation format aligns with federal and public works procurement expectations.

Delivery schedules are built around your receiving hours. Labeling can mirror your internal work order numbers, line locations, or installation zones.

To discuss powder coating and painting in Mooresville, NC, call 704-629-4879 or visit Farrisgrp.com to share drawings and coating specifications with our team.

Frequently Asked Questions about Painting and Powder Coating Services in Mooresville, NC

Can you match an existing equipment color from our plant?

Yes. We can work from RAL, major manufacturer codes, or physical color chips and provide sample panels for approval.

Do you handle different gloss levels on the same project line?

Yes. We can run matte, satin, and gloss finishes as long as colors and coating specifications are defined.

Can you package parts by production cell or project phase?

Yes. We can build kits and labels around your layout or project schedule.