Painting and Powder Coating Union SC | Industrial Finishing

We deliver industrial painting and powder coating in Union, SC for steel, stainless, and aluminum components used in material handling, utility equipment, and OEM assemblies.

Our finishing line operates with ISO 9001:2015 certification controls: pretreatment chemistry checks, booth parameter logs, cure verification, and calibrated inspection instruments.

Pretreatment Matrix and Film Build Targets

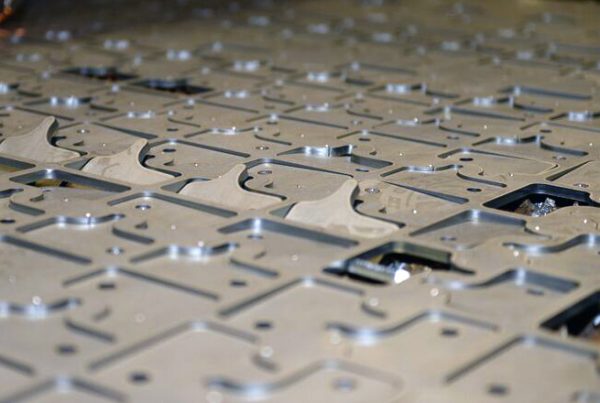

We clean and rinse, then apply iron phosphate for steel or zirconium conversion when programs specify elevated corrosion performance with lean chemistries. Where mill scale or weld discoloration is present, media blasting creates a consistent anchor profile. Masking plans use silicone caps, custom plugs, and high-temp tapes to protect threads, sealing faces, and ground paths.

Powder is applied with electrostatic guns tuned for kV and flow, and operators manage distance and wrap to reduce Faraday effects. Typical exterior DFT targets for polyester systems fall between 2.0 and 4.0 mils; super-durable grades are specified for high UV. Where prints specify liquids, we apply epoxy primer and 2K urethane topcoat for chemical resistance and color retention. Cure is verified with metal temperature probes and time-at-temperature logs. Post-cure checks may include adhesion, impact, gloss, and color against approved panels.

Records, Scheduling, Territories

We are a FedLinks Verified Federal Vendor, and provide submittal-ready packets with pretreatment logs, DFT charts, cure records, and inspection summaries. Deliveries are timed to your dock hours, and kitted pallets align with subsystem or phase labels. We support customers across the United States and internationally.

Book a finishing review for Union: 704-629-4879 or send drawings at Farrisgrp.com.

We support customers across the United States, Canada, and Turkey.

Frequently Asked Questions about Painting and Powder Coating Services in Union, SC

Can you supply color panels on our substrate?

Yes. Drawdowns can be prepared on matching material.

Do you log cure data for every batch?

Yes. Time-at-temperature records are retained with the traveler.

Can packaging be audited for finish protection?

Yes. We document edge guards, interleaves, and rack plans when requested.